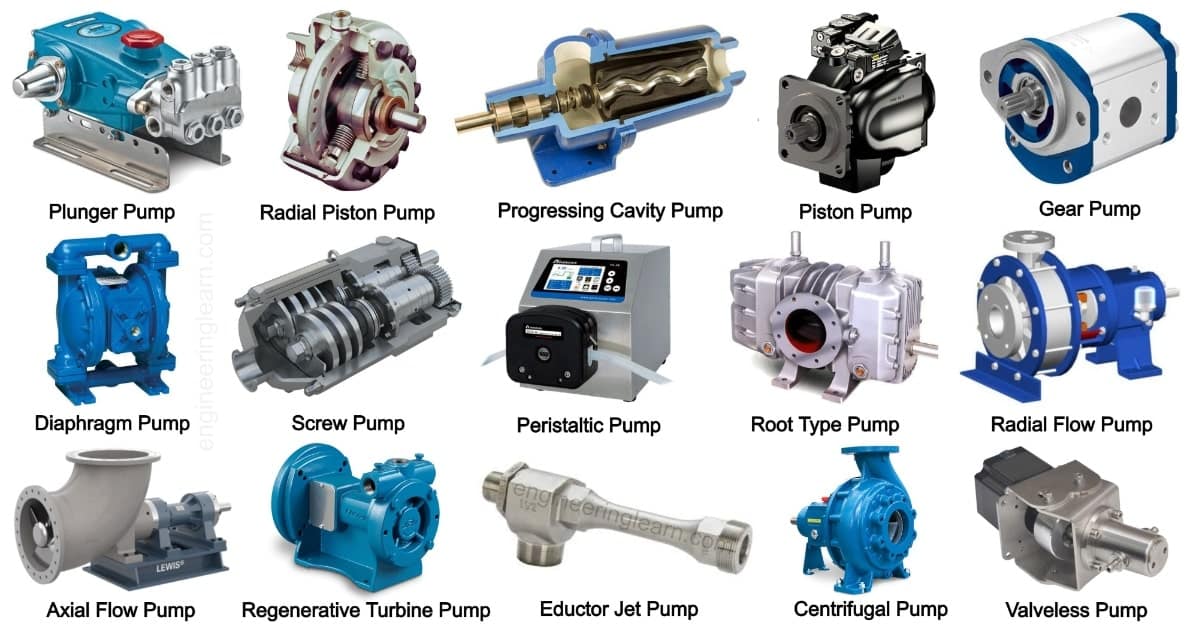

Types Of Pumps All In One Guide To Industrial Pump Types

Types Of Pumps All In One Guide To Industrial Pump Types Youtube As these elements turn, fluid is drawn into the spaces between the rotating parts and the pump casing and is enclosed in these spaces as they rotate and expel the fluid. gear pump, vane pump, screw pump, and peristaltic pump are the common types. while vane pumps are the most commonly used, gear pumps are also used for various industrial. Types of pumps | all in one guide to industrial pump typesin this video, we're going to learn what a pump is. and different types of pumps. we'll be looking.

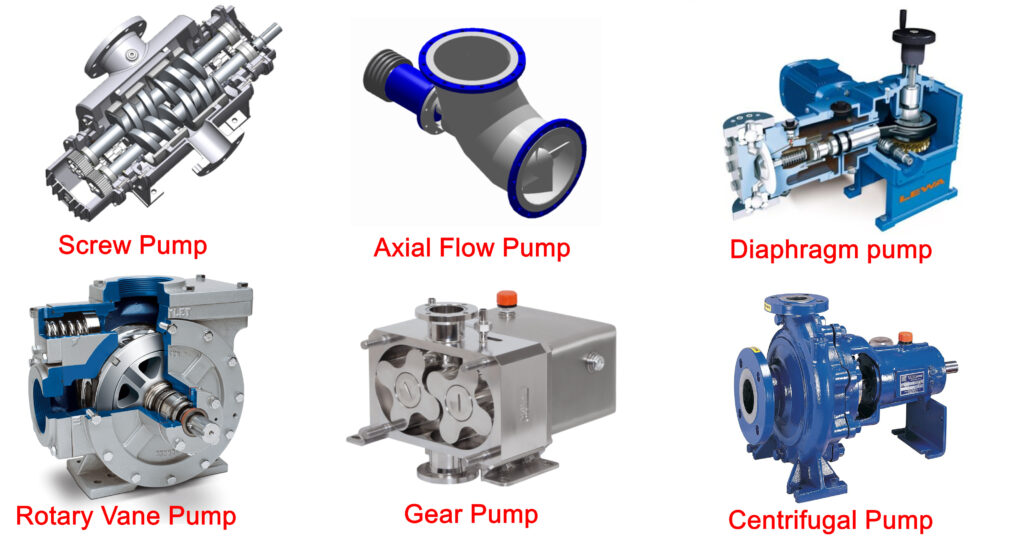

Different Types Of Pumps And Their Uses Complete Guide вђ Artofit Chemical industry: pumps are crucial for various processes in the chemical industry, ensuring efficient and safe handling of chemicals. different types of pumps are used in the chemical industry based on specific requirements: centrifugal pumps: ideal for transferring large volumes of liquids and slurries. Industrial pumps are designed specifically for use in harsh or heavy duty applications. they move a range of material types, including water and wastewater, chemicals, oil, petroleum, sludges and slurries, and food. this overview of pump varieties and applications will lend insight into which pumps are best suited for certain jobs. Essentially, there are two main categories of industrial pumps: dynamic and positive displacement pumps. dynamic pumps transport fluids through centrifugal force, the velocity of which is then converted into pressure that can be altered to regulate the flow of liquids through the pump. positive displacement pumps use diaphragms, pistons, or. 1. centrifugal pumps. the best choice for lower viscosity liquids and high flow rates. 2. ansi process pumps. incorporates dimensional standardization, which allows for the piping, foundation, and design to be completed before pump suppliers are even selected. also features more material options than other types. 3.

What Is Pump Types Of Pump Uses Working Application With Pictures Essentially, there are two main categories of industrial pumps: dynamic and positive displacement pumps. dynamic pumps transport fluids through centrifugal force, the velocity of which is then converted into pressure that can be altered to regulate the flow of liquids through the pump. positive displacement pumps use diaphragms, pistons, or. 1. centrifugal pumps. the best choice for lower viscosity liquids and high flow rates. 2. ansi process pumps. incorporates dimensional standardization, which allows for the piping, foundation, and design to be completed before pump suppliers are even selected. also features more material options than other types. 3. 1. centrifugal pumps: centrifugal pumps are among the most commonly used pump types in various industrial and commercial applications, primarily due to their simplicity, efficiency, and versatility. they operate on the principle of centrifugal force: as the pump’s impeller, which is a disk with vanes, rotates, it imparts kinetic energy to the. 1. centrifugal pumps. centrifugal pumps are the most common type of industrial pump used across most industries. these pumps move fluid using the transfer of rotational energy from one or more driven rotors, known as impellers. fluid enters the rotating impeller along the pump’s axis and is expelled by centrifugal force toward the pump’s.

Types Of Pumps Application Working Principles Linquip 1. centrifugal pumps: centrifugal pumps are among the most commonly used pump types in various industrial and commercial applications, primarily due to their simplicity, efficiency, and versatility. they operate on the principle of centrifugal force: as the pump’s impeller, which is a disk with vanes, rotates, it imparts kinetic energy to the. 1. centrifugal pumps. centrifugal pumps are the most common type of industrial pump used across most industries. these pumps move fluid using the transfer of rotational energy from one or more driven rotors, known as impellers. fluid enters the rotating impeller along the pump’s axis and is expelled by centrifugal force toward the pump’s.

13 Different Types Of Pumps And Their Uses

Comments are closed.