Part 4 How To Install A Ring Pinion In The Driveway Setting Up

Part 4 How To Install A Ring Pinion In The Driveway Setting Up 0:00 intro1:30 pressing on a pinion requires a press (use your friends)2:15 installing the race (find your spacer in video 3)3:30 install your pinion into th. 3. backlash ± the distance between the mating surfaces of the ring and pinion gears. adjusted by moving the ring gear inward or outward fro m the pinion gear by shimming the carrier. 4. carrier bearing preload ± the preload applied to the carrier bearings when installed in the axle housing. pinion depth is controlled by shims. shims.

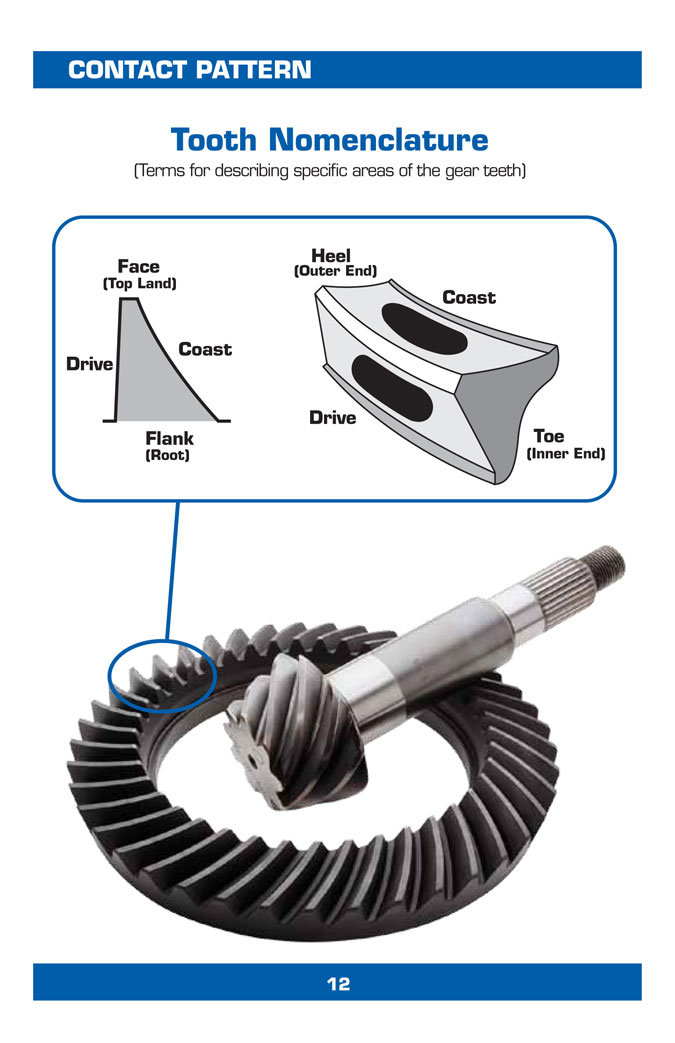

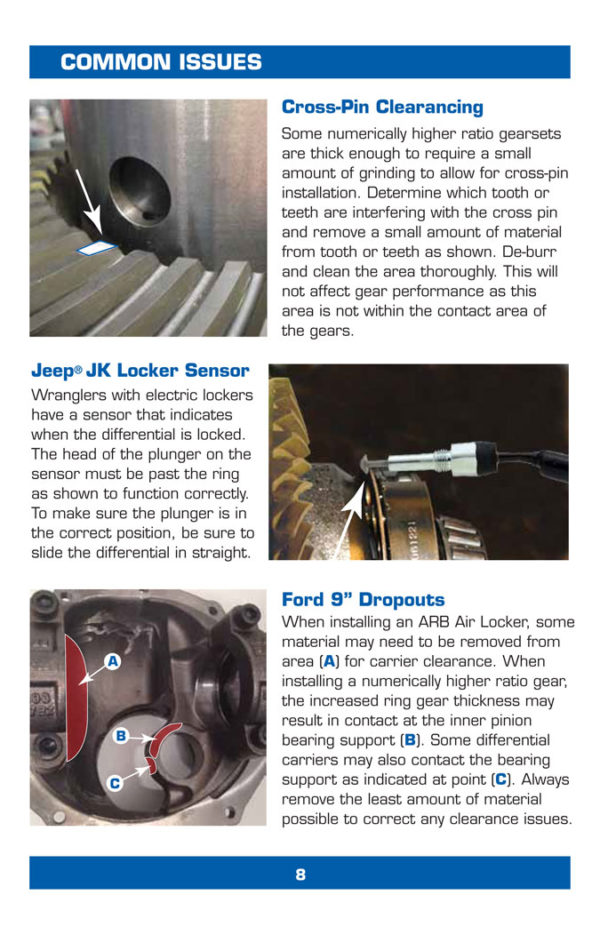

Ring Pinion Installation Instructions вђ The Ranger Station 10. each ring and pinion is pre run and marked on the pinion face with its proper depth setting called the “checking distance”. this dimension is from the face of the pinion to the axle center line. a setting tool must be used to measure the checking distance. pin ion depth is adjusted by adding or subtracting shim distance. Mark the bearings and use them for setting up the rear so that swapping shims becomes a 10 second job. then once your setup is perfect, remove the setup bearings and replace them with the other set of new bearings and you will never damage a bearing pulling it again – cheap and fool proof method of setting pinion depth and backlash to the. The pattern should be centered on the tooth from face to flank. there should usually be some clearance between the pattern and the top of the tooth (face), and always between the pattern and the bottom of the tooth (flank). pinion is too close. move the pinion away from the ring gear centerline. pinion is too far away. Mixed with another ring gear or pinion. check to see serial numbers are the same on the ring gear and pinion. 4. each gear set is pre run and marked on the pinion face with its proper depth setting called the “checking distance”. this dimension is from the face of the pinion to the axle centerline. a setting tool must be used to measure the.

Differential Ring And Pinion Gear Setup Youtube The pattern should be centered on the tooth from face to flank. there should usually be some clearance between the pattern and the top of the tooth (face), and always between the pattern and the bottom of the tooth (flank). pinion is too close. move the pinion away from the ring gear centerline. pinion is too far away. Mixed with another ring gear or pinion. check to see serial numbers are the same on the ring gear and pinion. 4. each gear set is pre run and marked on the pinion face with its proper depth setting called the “checking distance”. this dimension is from the face of the pinion to the axle centerline. a setting tool must be used to measure the. The ring and pinion manufacturer specified .007 .009. after a couple of trial runs, i felt confident enough to install the pinion. i put it in the freezer overnight, put the bearings in a 200 degree oven (the maximum recommended by the manufacturer), dropped on my two shims, then installed the inner bearing on the pinion. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. the images below illustrate both acceptable and unacceptable ring and pinion gear patterns. for more in depth information about ring and pinion gear patterns and how to make adjustments, see our installation instructions page. .

Ring Pinion Installation Instructions The Ranger Station The ring and pinion manufacturer specified .007 .009. after a couple of trial runs, i felt confident enough to install the pinion. i put it in the freezer overnight, put the bearings in a 200 degree oven (the maximum recommended by the manufacturer), dropped on my two shims, then installed the inner bearing on the pinion. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. the images below illustrate both acceptable and unacceptable ring and pinion gear patterns. for more in depth information about ring and pinion gear patterns and how to make adjustments, see our installation instructions page. .

Ring Pinion Installation Tools Bits Of Info Grumpys Performance

Comments are closed.