How To Wire A Plc Control Panel Like A Pro

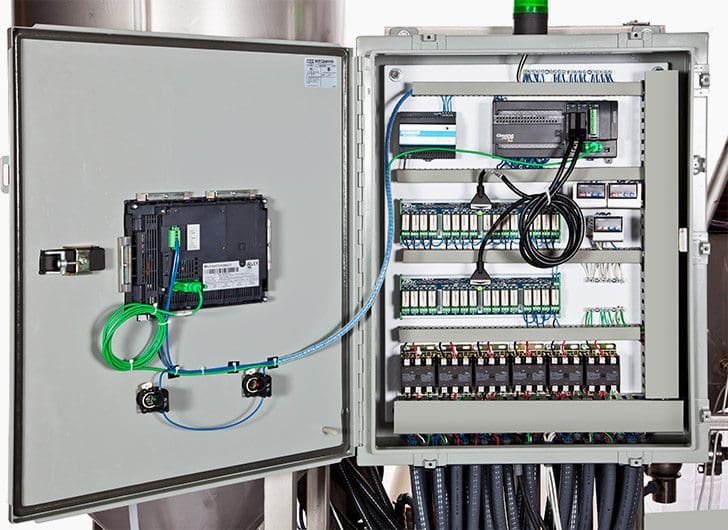

How To Wire A Plc Control Panel Free training course here: skool bee automation academywe help businesses and individuals build successful and profitable businesses and or. Once the power supply is installed, connect the plc to the control panel. this involves wiring the necessary inputs and outputs to the appropriate terminal blocks. carefully follow the manufacturer’s instructions and wiring diagram, ensuring that all connections are secure and properly labeled.

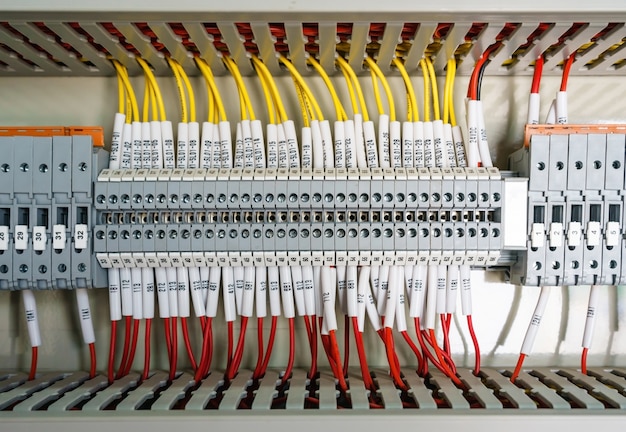

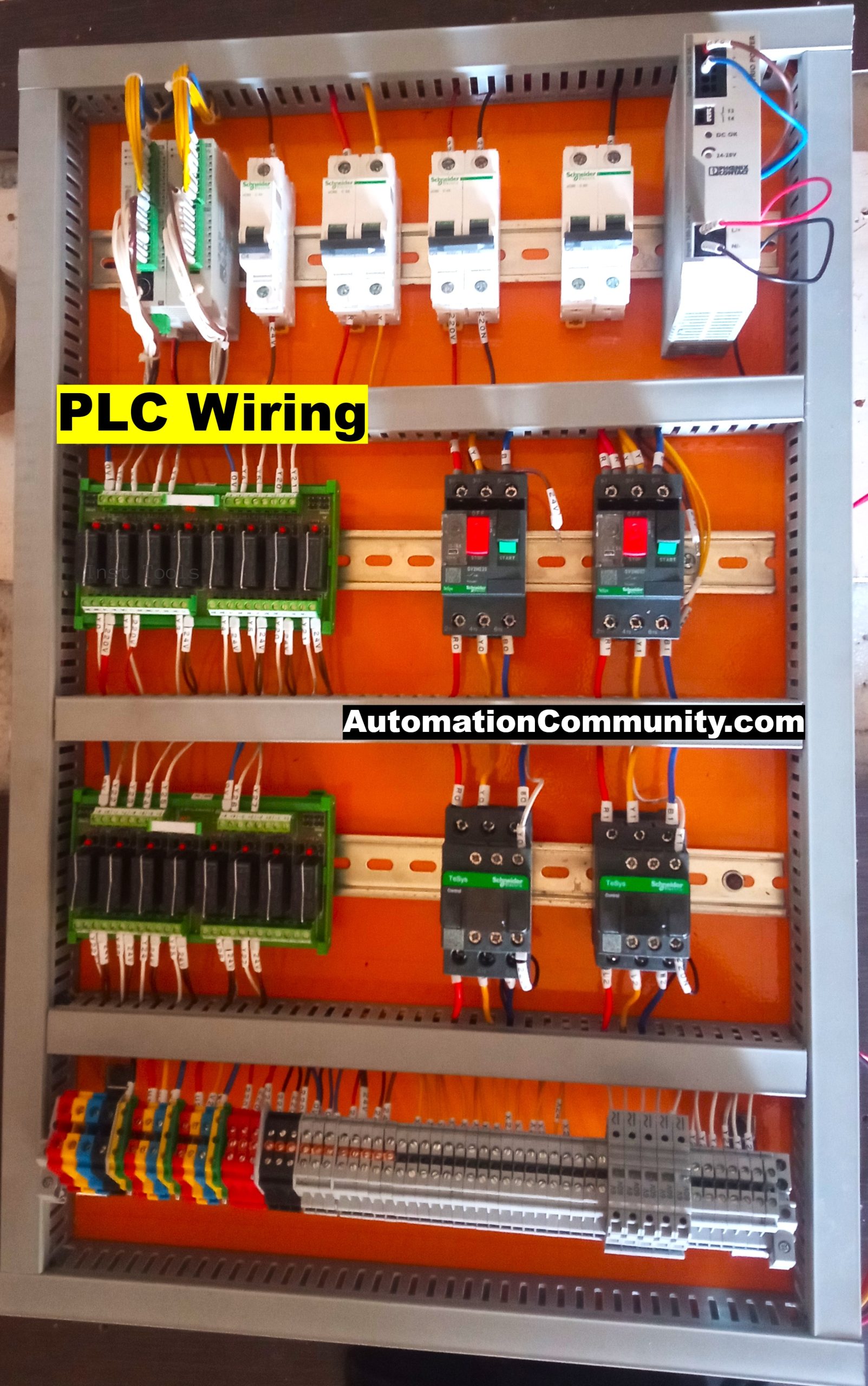

How To Wire A Plc Control Panel In this comprehensive video guide, we dive deep into the art of wiring a programmable logic controller (plc) control panel. whether you're a seasoned enginee. Electrical wiring diagrams of a plc panel. in an industrial setting a plc is not simply “plugged into a wall socket”. the electrical design for each machine must include at least the following components. a control system of a plc panel will normally use ac and dc power at different voltage levels. Digital inputs. firstly, take digital inputs. according to sink or source wiring, connect either 24v or 0v to the plc common. so, for example, if the common is 24v, connect 0v to all the respective plc field inputs in the terminal board. as one board has two pins, one will be used to provide 0v and the other will be connected to plc digital input. Plc (programmable logic controller) wiring connection is a crucial aspect of industrial automation systems. it involves connecting various components such as input and output devices, sensors, actuators, and power supplies to the plc in order to control and monitor the operation of a machine or a process. power supply connection: the first step.

How To Wire A Plc Control Panel Digital inputs. firstly, take digital inputs. according to sink or source wiring, connect either 24v or 0v to the plc common. so, for example, if the common is 24v, connect 0v to all the respective plc field inputs in the terminal board. as one board has two pins, one will be used to provide 0v and the other will be connected to plc digital input. Plc (programmable logic controller) wiring connection is a crucial aspect of industrial automation systems. it involves connecting various components such as input and output devices, sensors, actuators, and power supplies to the plc in order to control and monitor the operation of a machine or a process. power supply connection: the first step. Want to learn about industrial automation? go here: realpars individual pricing want to train your team in industrial automation? go here:. Once the i o modules are in place and their wires have been bundled, the wiring to the modules can begin. the following are ten recommended procedures for i o wiring: remove and lock out input power from the controller and i o before any plc installation and wiring begins. verify that all modules are in the correct slots.

How To Wire A Plc Control Panel Want to learn about industrial automation? go here: realpars individual pricing want to train your team in industrial automation? go here:. Once the i o modules are in place and their wires have been bundled, the wiring to the modules can begin. the following are ten recommended procedures for i o wiring: remove and lock out input power from the controller and i o before any plc installation and wiring begins. verify that all modules are in the correct slots.

How Is A Plc Control Panel Made For Industrial Machines

Comments are closed.