Formulation Development Of Aerosol

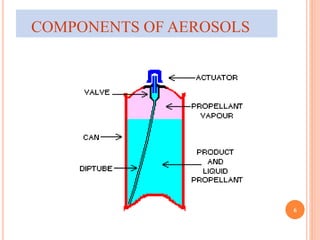

Formulation Development Of Aerosol Ppt Formulation & development of aerosol. this document provides an overview of aerosols for pharmaceutical use. it begins with introductions to aerosols and pharmaceutical aerosols. the main components of aerosols are then described, including propellants, containers, valves, and actuators. various aerosol systems like solution, suspension, and. Part ii common aerosol test methods. ph. a ph range of 9 to 10.5 is optimal for unlined steel containers. a ph range of 4.5 to 8.5 is optimal for aluminum containers. ph less than 8 problematic for unlined steel containers. ph can drift over product lifetime. do not depend on container linings alone.

Formulation Development Of Aerosol Ppt The extrafine aerosol formulation approach permits qvar ® to have a lower formulation drug concentration, increased inhalation technique tolerance and increased ratio of therapeutic efficacy to adverse effects because of the deposition of the drug in the peripheral airways compared to the cfc formulation (79,80). Aerosol product formulations scope –this presentation will focus on the basic format of a chemical formulation, involving a component to component compatibility test. it’s a useful elimination process that help shorten the formulation development. chemical formulation –is the process by which. There is clearly an increasing interest in pulmonary drug delivery over the last few decades. as an indication, at the time of writing, a simple pubmed search using the term “inhaled formulations” yielded almost >2300 results for the time period 2010–2019, while the same search yielded <1350 results for the previous decade (2000–2009) and <420 results for the 10 year period until 1999. A pharmaceutical aerosol must satisfy certain standards to claim it to be a quality therapeutic perform drug, so it is mandatory to maintain their quality by variegated numbers evaluation, based on the series of tests carried out during the formulation development and finished product testing stages based on pharmacopeias standards and.

Formulation Development Of Aerosol There is clearly an increasing interest in pulmonary drug delivery over the last few decades. as an indication, at the time of writing, a simple pubmed search using the term “inhaled formulations” yielded almost >2300 results for the time period 2010–2019, while the same search yielded <1350 results for the previous decade (2000–2009) and <420 results for the 10 year period until 1999. A pharmaceutical aerosol must satisfy certain standards to claim it to be a quality therapeutic perform drug, so it is mandatory to maintain their quality by variegated numbers evaluation, based on the series of tests carried out during the formulation development and finished product testing stages based on pharmacopeias standards and. Mdi comprises of drug formulation, propellant, metering valve, actuator, and container. this review contains overview of excipient selection, primary packaging material, propellant selection and formulation development of pmdi. two of the most commonly used methods for the manufacturing of mdis are cold filling method and pressure filling method. As indicated, it is very valuable to have knowledge during formulation development with respect to an understanding of the influence of physicochemical properties of liquids (i.e. surface tension and viscosity) on aerosol droplet size and output for these inhaler devices. 23 the addition of surface active agents to water changes the secondary.

Comments are closed.