Baking Baking Processes Bakerpedia

Bread Processing Baking Processes Bakerpedia Baking is the final step in making yeast leavened (bread, buns, rolls, crackers) and chemically leavened products (cakes, cookies). it’s a thermal process that uses an oven, which transfers heat to the dough pieces via: conduction through heated surfaces. convection through hot air. radiation from heat sources such as flames. Chorleywood baking process. choux pastry. ciabatta. cinnamon roll. clean in place (cip) clean label. clean label bread. clean label cake. cocoa alkalization.

Baking Baking Processes Bakerpedia Oven baking parameters cover five key variables that are involved in transforming dough or batter into a finished product. these parameters can be measured and controlled during the baking step. understanding their interactions and role in producing high quality products is considered both an art and science. the parameters include: temperature. Ovens are an integral component of food and other manufacturing processes. their design takes into consideration the overall plant layout as well as the type and estimated production volume. in baking operations, ovens are responsible for transferring heat to bring dough pieces to baking temperatures. baking is a simultaneous heat and mass. Get our weekly newsletter and sharpen your technical baking knowledge. resilience is defined as the ability of a material to absorb energy when it is deformed elastically and to release that energy upon unloading. bread’s resilience is its ability to spring back, returning to its original shape when subjected to a compressing force. Depositing. baking: baking times and temperatures vary with the scaling deposited weight and size of the pan. baking temperatures are typically 177–204°c (350–400°f), with a bake time of 45–55 minutes for large tube pan and 20–30 minutes for small tube pans. the cake is done when the surface springs back from a light finger impression.

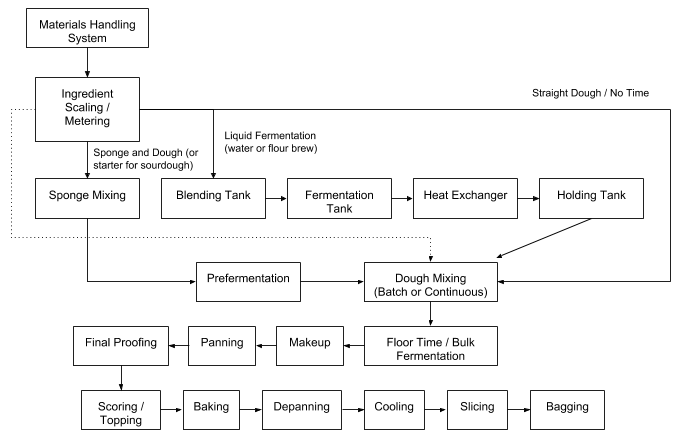

Baking Processes Bakerpedia Get our weekly newsletter and sharpen your technical baking knowledge. resilience is defined as the ability of a material to absorb energy when it is deformed elastically and to release that energy upon unloading. bread’s resilience is its ability to spring back, returning to its original shape when subjected to a compressing force. Depositing. baking: baking times and temperatures vary with the scaling deposited weight and size of the pan. baking temperatures are typically 177–204°c (350–400°f), with a bake time of 45–55 minutes for large tube pan and 20–30 minutes for small tube pans. the cake is done when the surface springs back from a light finger impression. It consists of a series of steps including mixing, fermentation, makeup, proofing, baking, cooling, slicing and packaging. due to their critical role, these processes must be carefully operated to meet pre set conditions and specifications. the following block diagram shows the production steps in bread processing using different dough systems. Everything commercial baking in one spot. bakerpedia has gifted the american society of baking members with the ultimate index of commercial baking information. you’ll find articles on food safety, recipes, analytical methods, equipment, and more. anything you need to know about the commercial baking industry, we’ve got it.

Comments are closed.